That is around the grounds that vertical machining centers Generally have lesser beds. For Companies who need to machine huge Workpieces, scaled-down beds is usually a significant difficulty for them.

Go on reading, We'll elaborate on 12 distinctive CNC machines in detail with a brief guidebook on selecting the right machine on your project at the end.

Turn on the main power supply, accompanied by the ability offer on the CNC system, then the facility supply in the servo system, and finally launch the unexpected emergency end button to reduce the impact on the electrical elements on the CNC system and enhance its service existence.

Its components have strong patterns to deliver top-quality torque, horsepower, and machining pace. The extent of automation of vertical milling centers also makes it possible for them to cut a variety of elements and cut down Over-all manufacturing costs.

The PCNC 440 is built not only for smaller outlets or hobbyists but for almost any machine store hunting for a sound secondary Procedure. Optional 4th axis rotary attachments could be extra, generating this smaller milling machine a complex juggernaut.

The spindle axis of your machining center is positioned perpendicular to the workbench. The machine has a considerable, portal-design body consisting of double columns as well as a leading beam. The double columns are joined by a central beam, which makes it ideal for processing huge and complexly shaped workpieces.

Presently, numerical Command machine tools have several advantages around classic machine tools and are being extensively Employed in the machining sector.

The Resource changer increases the efficiency in the vertical machine center by allowing for the automated collection of tools for various duties starting from tough cutting to high-quality-hole unexciting.

Considered one of the best great things about vertical machining centers is that they're considerably more productive than horizontal machining centers. This really is to the grounds that vertical machining centers can carry out distinct functions simultaneously, like milling, drilling, and tapping.

All through using the NC machine Software, it is crucial to manage it within just its working parameters to avoid harm to the machine. For instance, the workpiece and fixtures placed on the workbench from the machining center and NC milling machine mustn't exceed the most load ability in the workbench, otherwise it could harm the transferring information rail.

When subjected to exterior interference, the info will be missing or perplexed, and the machine tool will never do the job Generally.

Specially with the external auxiliary equipment: if there is a hydraulic system pump station, Examine if the quantity of hydraulic oil is ample; for those with the air force system, regularly drain the air compressor and gasoline storage pressure vessel to forestall excessive dampness from accumulating and moving into the machine Device under the pressure of air flow, which may lead to corrosion and harm to parts and parts.

After further more evaluate, we Find out more think this CNC milling machine is fully effective at staying a real workhorse in any machine shop or garage. We will happily say this is the low cost CNC Mill choice for These over a strict spending budget.

It is strictly prohibited to load tools which might be overweight or way too lengthy in to the Resource journal to avoid the manipulator from dropping the tool or creating collisions With all the workpiece, fixture, etcetera.

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Mara Wilson Then & Now!

Mara Wilson Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

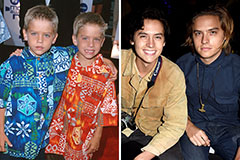

Alana "Honey Boo Boo" Thompson Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Katey Sagal Then & Now!

Katey Sagal Then & Now!